How to Make Pigment Powder?

Creating pigment powder involves a meticulous process that transforms raw materials into vibrant colors used in various industries, from paints to cosmetics. One of the most efficient methods to achieve high-quality pigment powder is through spray drying. This article will delve into the detailed steps of making pigment powder and highlight the critical role of spray dryers in the process.

Understanding Pigment Powder

Pigment powders are finely ground solid particles that impart color to other materials. Unlike dyes, which dissolve in a medium, pigments remain suspended, providing a consistent and lasting color. They are used in a variety of applications, including:

Paints and coatings

Plastics and polymers

Cosmetics

Inks

Textiles

Raw Materials and Preparation

The first step in making pigment powder is selecting the appropriate raw materials. These can include natural sources like minerals and plants, or synthetic chemicals. The choice of raw materials depends on the desired color, properties, and application of the pigment.

What raw materials are commonly used in pigment production?

Some commonly used raw materials include:

Titanium dioxide for white pigments

Iron oxides for reds, yellows, and browns

Chromium oxide for green pigments

Ultramarine for blue pigments

Organic compounds for a range of vibrant colors

The Process of Making Pigment Powder

1. Mixing and Precipitation

The chosen raw materials are mixed in precise proportions. This mixture is then subjected to a chemical reaction, often precipitation, to form pigment particles. Precipitation involves adding a precipitating agent to the solution, causing the pigment particles to form and settle out of the mixture.

2. Filtration and Washing

After precipitation, the pigment slurry is filtered to separate the solid particles from the liquid. The solid pigment particles are then washed to remove any impurities or unreacted chemicals. This step is crucial to ensure the purity and quality of the final pigment powder.

3. Drying

The washed pigment particles need to be dried to remove any remaining moisture. This is where the spray dryer plays a significant role. Spray drying is a highly efficient method that converts the liquid pigment slurry into a fine powder.

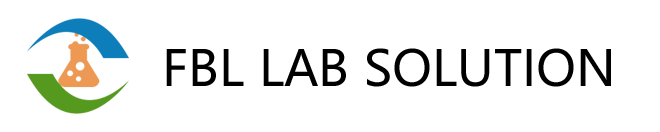

The Role of Spray Dryers in Pigment Powder Production

Spray dryers are essential in the pigment production process for several reasons:

Efficiency and Consistency

Spray drying involves atomizing the liquid pigment slurry into a fine mist and then rapidly drying it using hot air. This process ensures that the pigment particles are uniformly dried, resulting in a consistent and fine powder. The rapid drying also helps preserve the pigment's color and properties.

Versatility

Spray dryers can handle a wide range of pigment slurries, regardless of their viscosity or solid content. This versatility makes them ideal for producing various types of pigment powders.

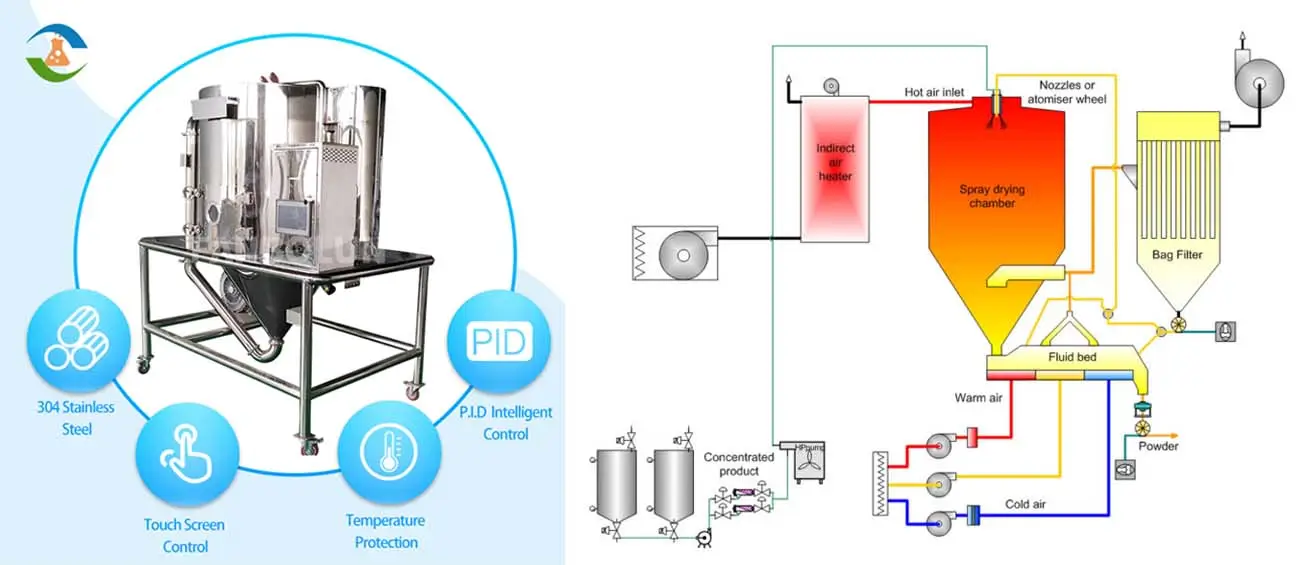

Spary Drying Machine Pilot Plant

Cost-Effectiveness

Spray drying is a cost-effective method for producing pigment powders on a large scale. It allows for continuous production, reducing downtime and increasing overall efficiency.

How does spray drying compare to other drying methods in pigment production?

Spray drying offers several advantages over traditional drying methods like oven drying or freeze drying. These include:

Faster drying times

Better control over particle size and distribution

Higher purity and quality of the final product

Reduced risk of contamination

Post-Drying Processes

4. Milling

Once the pigment powder is dried, it may require further milling to achieve the desired particle size and texture. Milling can be done using various equipment, such as ball mills, jet mills, or roller mills. This step ensures that the pigment powder meets the specific requirements of its intended application.

5. Surface Treatment

In some cases, pigment powders undergo surface treatment to enhance their performance characteristics. Surface treatments can improve properties like dispersibility, stability, and compatibility with different mediums. Common surface treatments include coating the pigment particles with silanes, siloxanes, or other chemical agents.

6. Quality Control

Quality control is a critical step in the pigment production process. The final pigment powder is tested for various parameters, including:

Particle size and distribution

Color strength and consistency

Purity and absence of contaminants

Dispersibility in different mediums

Ensuring high-quality pigment powder is essential to meet industry standards and customer expectations.

Applications of Pigment Powder

Pigment powders are used in a wide range of applications, each requiring specific properties and performance characteristics. Some of the key applications include:

Paints and Coatings

Pigments provide color, opacity, and protection to paints and coatings. They are used in architectural paints, industrial coatings, automotive paints, and more. The quality of the pigment powder directly impacts the performance and durability of the paint.

Plastics and Polymers

In the plastics industry, pigment powders are used to color and enhance the properties of various polymer products. From household items to automotive parts, pigments play a crucial role in the aesthetics and functionality of plastic products.

Cosmetics

Pigment powders are widely used in cosmetics to provide color to products like eyeshadows, lipsticks, and foundations. The safety and quality of cosmetic pigments are paramount, as they are applied directly to the skin.

Inks

Printing inks rely on high-quality pigment powders to produce vibrant and long-lasting colors. Pigments are used in various types of inks, including offset, flexographic, and screen printing inks.

Textiles

In the textile industry, pigments are used to color fabrics and fibers. Pigment printing and dyeing processes require pigments that offer excellent colorfastness and durability.

Conclusion

Producing high-quality pigment powder involves a series of carefully controlled steps, from raw material selection to final quality control. Spray drying is a critical component of this process, offering efficiency, consistency, and versatility in producing fine pigment powders.

By understanding the intricacies of pigment production and the role of spray dryers, manufacturers can achieve superior results and meet the diverse needs of various industries. Whether it's for paints, plastics, cosmetics, or textiles, high-quality pigment powders are essential for creating vibrant, durable, and visually appealing products.

What are the key benefits of using high-quality pigment powders in industrial applications?

Using high-quality pigment powders offers several benefits, including:

Enhanced color consistency and vibrancy

Improved product performance and durability

Greater compatibility with different mediums

Compliance with industry standards and regulations

Incorporating these best practices and technologies into the pigment production process ensures that manufacturers can deliver exceptional products that meet the highest standards of quality and performance.

How to Make Egg White Powder at Home?

Separate egg whites from yolks, dry them thoroughly using a dehydrator or low-temperature oven, and then grind the dried egg whites into a fine powder using a...

How to Make Quality Instant Coffee at Home?

Making quality instant coffee at home is easy: grind your beans finely, sieve the grounds, store in an airtight container, add hot water, stir well, and custo...

How to Make Milk Powder?

Milk is pasteurized, concentrated through evaporation, then spray-dried into powder. It is cooled and packaged. Quality control ensures nutrient retention, so...