What Are the Benefits of Spray Drying?

When it comes to processing liquids into powders, spray drying is one of the most effective methods out there. But why is spray drying so popular? What are its real benefits? Whether you're a manufacturer looking to streamline your operations or someone just curious about this nifty technology, this article will break down everything you need to know about spray drying and why it might just be the answer to your problems.

What is Spray Drying?

Let’s start with the basics: Spray drying is a process that turns a liquid or slurry into a dry powder. Sounds like magic, right? But it's all science. In a nutshell, the liquid is sprayed into a hot drying chamber where the water quickly evaporates, leaving behind a fine powder.

Think about how we dry clothes in the dryer. Now, imagine you're drying a drink, sauce, or even a medicine. Spray drying is like that, but on a much larger scale. From food to pharmaceuticals, spray drying is used in many industries for one reason: it works wonders!

1. Quick and Efficient Processing

One of the biggest advantages of spray drying is its speed. When you need to turn a liquid into powder, time matters. Conventional drying methods, like air drying, can take a lot of time and energy. But spray drying? It gets the job done in a flash.

Why does this matter? Because it means businesses can process large quantities in less time. This increases efficiency, reduces downtime, and ultimately saves money. Quick turnaround is crucial in industries where product availability and shelf life are everything.

So, what's faster than drying liquids by traditional means? Spray drying. In fact, it’s one of the fastest drying methods available, making it the go-to choice for many industries.

2. Saving Money, And It Is Worth Investing In Buying!

If you're running a business, cutting costs while improving quality is always on your mind. And here’s the good news: Spray drying can actually help save money in the long run. How? Well, because of its speed and efficiency, the energy consumption tends to be lower than other drying methods.

The reduced energy costs, combined with the higher throughput, make it a cost-effective solution. For companies that need to process large volumes of liquid, the investment in spray drying equipment can lead to big savings. So, while the initial investment in the machinery might seem steep, the return on investment (ROI) can be well worth it. It's a win-win for manufacturers who need a reliable, efficient solution that doesn’t break the bank.

3. Range of Applications

One of the best things about spray drying is its versatility. From food and beverages to chemicals and pharmaceuticals, this process can handle a wide variety of liquids. For example, think of powdered milk, powdered coffee, or even flavorings and seasonings – all made possible by spray drying.

But the beauty of spray drying doesn't stop there. It’s also widely used in the pharmaceutical industry for creating powders for inhalers, medicine tablets, and nutritional supplements. Even in the cosmetic industry, spray drying is used to create powders for makeup or skincare products.

Doesn't it make you wonder how many everyday products we use are created through spray drying? From your morning coffee to the medicine you take when you're feeling under the weather, spray drying is working quietly behind the scenes.

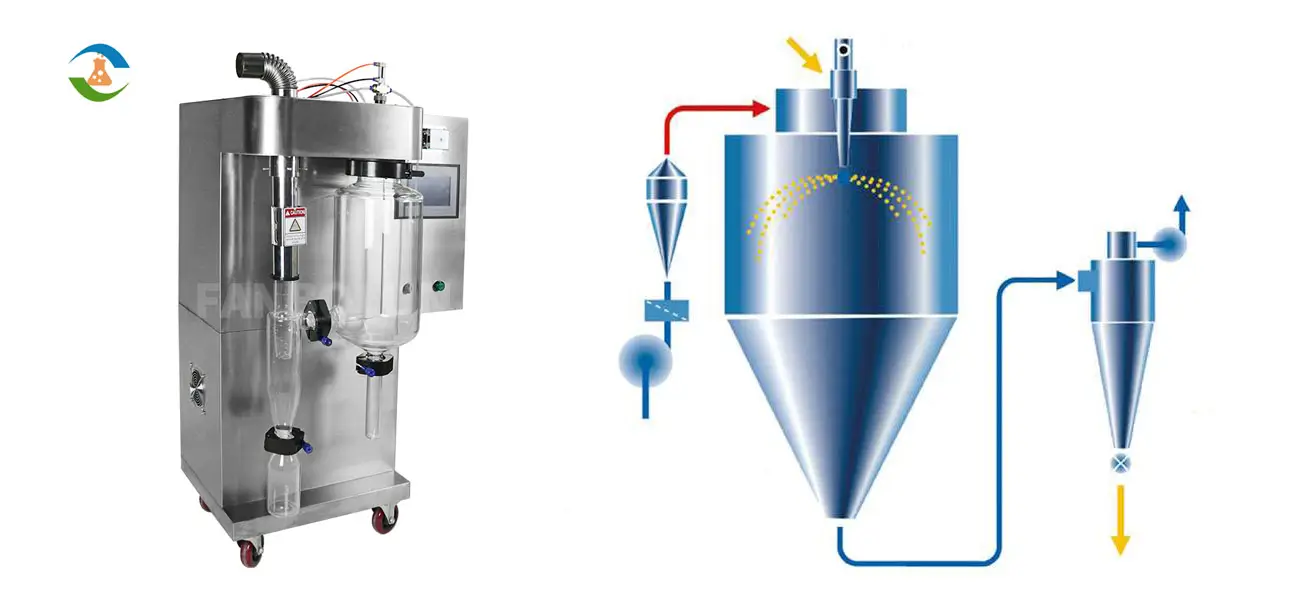

Spary Drying Machine Pilot Plant

4. Improved Shelf Life

Have you ever opened a bag of powdered soup mix or baby formula and noticed that it lasts for months, even years, without going bad? That's thanks to the drying process that removes moisture and reduces the chances of bacterial growth. Moisture is the enemy when it comes to preserving food, pharmaceuticals, and other products. By removing it quickly, spray drying ensures that products stay fresh for longer.

The ability to preserve products and extend their shelf life is a huge benefit for manufacturers, especially in the food and pharmaceutical industries. Not only does this reduce waste, but it also increases the product's marketability. People love products that last longer and maintain their quality over time, and spray drying helps make that happen.

5. Maintaining Nutrients and Quality

Do you ever worry about the nutrients in your food or medicine being destroyed during processing? This is a common concern, but spray drying does an excellent job of preserving the quality of sensitive ingredients. Because spray drying works quickly and doesn’t involve high temperatures for extended periods, it helps maintain the integrity of vitamins, enzymes, and other delicate compounds.

Take fruit powders, for example. If you were to dry fruit using traditional methods, the heat and slow drying could degrade many of the nutrients. But with spray drying, the rapid evaporation of water locks in those nutrients, resulting in a powder that’s just as nutritious as the fresh fruit itself. It’s not just about getting the product dry – it’s about getting it dry while maintaining its quality.

6. Uniformity and Consistency

Have you ever bought a powdered product only to find that the consistency isn’t the same throughout? Some parts may be clumpy, others may be too fine, or the flavor might be inconsistent. Spray drying helps solve this issue by producing powders that are uniform and consistent.

The process ensures that each particle of the product is of the same size and texture, which is especially important in products like baby formula, pharmaceuticals, and food ingredients. This consistency in quality leads to more predictable outcomes, better customer satisfaction, and fewer product recalls.

7. Environmentally Friendly and Sustainable

In today’s world, everyone is thinking more about the environment. So, is spray drying eco-friendly? The answer is yes, but with some caveats. While spray drying does use energy, the process is designed to be efficient and can be optimized for energy conservation. For instance, many modern spray drying systems use energy recovery systems to recycle heat and reduce overall energy consumption.

Additionally, since the process minimizes waste and ensures the preservation of valuable nutrients, there’s less need to throw out excess product. So, in the grand scheme of things, spray drying can be seen as a more sustainable option compared to other drying methods that generate more waste and consume more energy.

Why Spray Drying Is the Future of Manufacturing

At the end of the day, the benefits of spray drying are clear. It’s fast, efficient, cost-effective, and versatile, with a wide range of applications in industries from food to pharmaceuticals. It allows manufacturers to preserve the quality of their products, extend shelf life, and save money.

And, as we continue to look for more sustainable and efficient ways to process materials, spray drying will likely remain one of the top choices. So, next time you pick up a can of powdered milk or a packet of instant coffee, remember that spray drying was likely the key to getting it into that form – and that’s no small feat!

Whether you’re a business looking for a reliable drying method or a curious mind just learning about industrial processes, spray drying stands out as a powerful tool in modern manufacturing. It’s not just about making things dry – it’s about making them better, faster, and more efficient.

What do you think? Could spray drying be the solution you've been looking for?

What is a Spray Dryer Used for in a Laboratory?

A spray dryer in a laboratory converts liquid solutions into dry powders. It’s essential for producing consistent, stable, and high-quality powders for pharma...

What is Spray Drying?

Spray drying is a process that transforms liquid or slurry into dry powder. It involves rapidly evaporating moisture with hot gas, producing fine, uniform par...

What is a Spray Dryer Used For?

A spray dryer transforms liquids into dry powders using hot gas. It's extensively used in food, pharmaceutical, chemical, and ceramic industries for producing...