What is Spray Drying?

Have you ever wondered how powdered milk, instant coffee, or even powdered soups are made? You might be surprised to learn that the magic behind these everyday products lies in a fascinating process called spray drying. But what exactly is spray drying, and why is it such a crucial method in the food and pharmaceutical industries? Let’s dive in and find out.

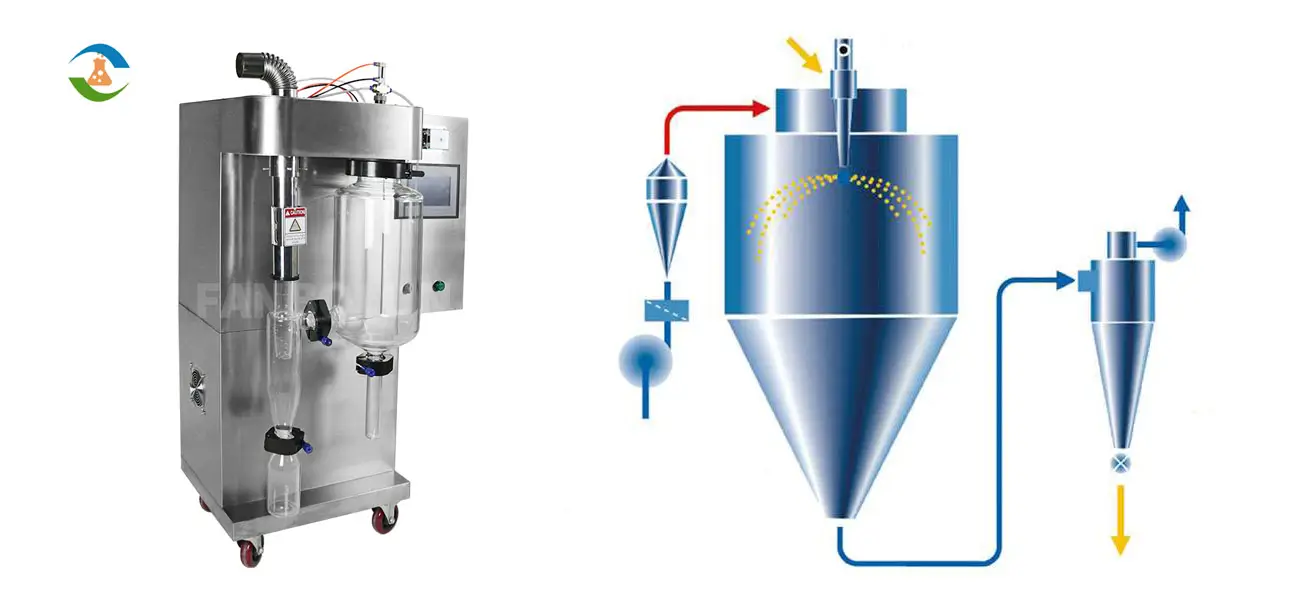

Spray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying it with a hot gas. This might sound complicated, but it’s actually a pretty straightforward process once you break it down. Essentially, a liquid mixture is sprayed into a chamber where hot air rapidly evaporates the moisture, leaving behind tiny particles of dry powder. This method is widely used because it’s efficient and versatile, making it possible to produce powders from a variety of liquid substances.

The Process of Spray Drying: Breaking It Down

So, how does spray drying work? Imagine you have a liquid mixture – this could be anything from a coffee extract to a pharmaceutical solution. This mixture is first pumped into a spray dryer, where it's atomized into fine droplets by a nozzle or rotary atomizer. These droplets are then exposed to a stream of hot air. The hot air quickly evaporates the moisture from the droplets, leaving behind dry particles that are collected as powder.

It’s kind of like when you spray water into a hot oven – the water droplets quickly evaporate, leaving nothing but a dry residue. The key to spray drying is controlling the size of the droplets and the temperature of the air. This ensures that the drying is rapid and the particles are uniform in size, which is crucial for many applications.

Why is Spray Drying So Important?

You might be wondering, why go through all this trouble to make powder? The answer lies in the many benefits that spray drying offers.

1. Preservation and Shelf Life: One of the primary reasons for spray drying is to preserve the product. By removing moisture, the growth of microorganisms is inhibited, significantly extending the shelf life of the product. This is why powdered milk can last for months or even years without spoiling.

2. Easy Handling and Storage: Powders are much easier to handle and store compared to liquids. They take up less space and are less prone to spillage and contamination. This makes transportation and storage much more convenient.

3. Consistent Quality: Spray drying produces uniform particles, which is essential for ensuring consistent quality in the final product. This uniformity is particularly important in industries like pharmaceuticals, where precise dosages are critical.

4. Versatility: Spray drying can be used with a wide range of products, from food and beverages to pharmaceuticals and chemicals. This versatility makes it a go-to method for many industries.

The Science Behind Spray Drying

Let’s get a bit scientific for a moment. The efficiency of spray drying depends on several factors, including the temperature of the hot air, the rate at which the liquid is fed into the dryer, and the size of the droplets. By optimizing these parameters, manufacturers can achieve the perfect balance between drying speed and product quality.

But here’s a question to ponder: How does the temperature affect the quality of the final product? Higher temperatures can speed up the drying process, but they can also cause heat-sensitive components to degrade. On the other hand, lower temperatures might preserve these components but take longer to achieve the desired dryness. Finding the sweet spot is key to producing a high-quality powder.

Applications of Spray Drying

Spray drying isn’t just a fancy process; it has real-world applications that impact our daily lives. Here are a few examples:

1. Food Industry: Spray drying is widely used in the food industry to produce powdered products like milk, coffee, and spices. These powders are not only convenient but also retain much of the original flavor and nutrients of the liquid product.

2. Pharmaceuticals: In the pharmaceutical industry, spray drying is used to create powders for inhalers, tablets, and capsules. The ability to produce uniform particles is crucial for ensuring consistent dosages and effective delivery of medication.

3. Chemicals: Spray drying is also used in the production of detergents, ceramics, and other chemical products. The process ensures that these powders have the right properties for their intended use.

Advantages of Spray Drying

Let’s talk about some of the specific advantages of spray drying that make it such a popular method:

1. Saving Money Is The Last Word, And It Is Worth Investing In Buying! Spray drying is highly efficient, which means it can produce large quantities of powder quickly and at a relatively low cost. This efficiency translates to savings for manufacturers and, ultimately, consumers.

To evaluate the economic benefits of using a spray dryer with updated parameters, we'll use the following data:

| Item | Value |

| Initial Cost of Spray Dryer | $10,000 |

| Monthly Operating Cost | $2,000 |

| Max Water Evaporation Capacity | 6L/hour |

| Product Output | 6kg/hour |

| Product Selling Price | $20/kg |

| Monthly Working Hours | 160 hours |

| Monthly Production | 960kg |

| Monthly Revenue | $19,200 |

| Monthly Total Cost | $2,000 |

| Monthly Net Profit | $17,200 |

LPG-5L Spary Drying Machine Pilot Plant

Monthly Production = 6kg/hour * 160 hours/month = 960kg/month

Monthly Revenue = 960kg/month * $20/kg = $19,200/month

Monthly Total Cost = $2,000 (operating cost)

Monthly Net Profit = $19,200 (revenue) - $2,000 (total cost) = $17,200

Based on the table and calculations, the monthly net profit from using the spray dryer is $17,200. This shows a significant economic benefit, with a quick payback period given the initial cost of $10,000.

2. Improved Product Stability: The removal of moisture not only extends the shelf life of the product but also makes it more stable. This is particularly important for products that are sensitive to moisture and temperature changes.

3. Customization: Spray drying allows for a high degree of customization. Manufacturers can adjust the parameters of the process to produce powders with specific properties, such as particle size, density, and solubility. This flexibility is invaluable for meeting the diverse needs of different industries.

Challenges and Considerations

While spray drying offers many benefits, it’s not without its challenges. One of the main considerations is the initial cost of setting up a spray drying system. The equipment can be expensive, and there’s a need for skilled operators to ensure the process runs smoothly.

Another challenge is the potential for heat-sensitive components to degrade during the drying process. This is why it’s crucial to carefully control the temperature and other parameters to minimize any negative impact on the final product.

But here’s another thought-provoking question: What steps can be taken to protect heat-sensitive ingredients during spray drying? One approach is to use lower drying temperatures, though this can lengthen the process. Another option is to encapsulate the sensitive ingredients in a protective coating before spray drying. This adds a layer of complexity to the process but can help preserve the quality of the final product.

The Future of Spray Drying

As technology advances, so too does the potential for spray drying. Innovations in equipment design and process control are making it possible to produce even higher quality powders with greater efficiency. There’s also growing interest in using spray drying for new applications, such as producing nanoparticles for drug delivery and creating advanced materials for electronics.

In the food industry, there’s potential for spray drying to play a role in producing plant-based proteins and other novel ingredients. As consumer demand for these products grows, spray drying could become an essential part of the manufacturing process.

Conclusion

Spray drying might seem like a complex process, but it’s actually a straightforward and incredibly useful method for transforming liquids into powders. Its applications are vast, ranging from food and beverages to pharmaceuticals and chemicals. The benefits of spray drying, including preservation, easy handling, and consistent quality, make it a valuable tool in many industries.

So, the next time you enjoy a cup of instant coffee or use powdered milk in a recipe, you’ll know a bit more about the fascinating process that made it possible. And if you’re in the manufacturing business, considering spray drying could open up new possibilities for creating high-quality, cost-effective products.

In the end, spray drying isn’t just about making powders; it’s about innovation, efficiency, and meeting the ever-changing needs of consumers. Whether you’re a curious consumer or a savvy business owner, understanding the ins and outs of spray drying can give you a new appreciation for this incredible technology.

What Are the Benefits of Spray Drying?

Spray drying is a fast, cost-effective method that turns liquids into powder. It preserves nutrients, extends shelf life, enhances consistency, and is widely ...

What is a Spray Dryer Used for in a Laboratory?

A spray dryer in a laboratory converts liquid solutions into dry powders. It’s essential for producing consistent, stable, and high-quality powders for pharma...

What is a Spray Dryer Used For?

A spray dryer transforms liquids into dry powders using hot gas. It's extensively used in food, pharmaceutical, chemical, and ceramic industries for producing...