What is a Spray Dryer Used for in a Laboratory?

Spray dryers are indispensable tools in many laboratories, but what exactly do they do, and why are they so important? Let's dive into the fascinating world of spray drying and discover how this technology can revolutionize your laboratory processes.

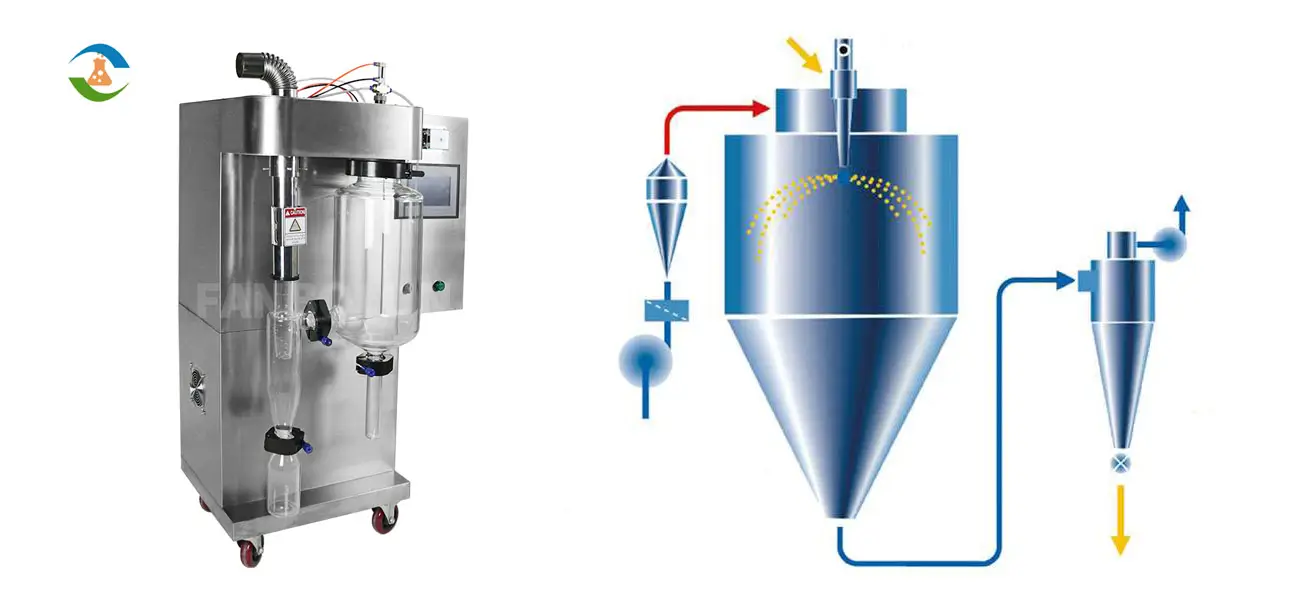

What is a Spray Dryer?

A spray dryer is a piece of equipment that transforms liquid solutions into dry powders. This is done by spraying the liquid into a hot drying medium, typically air. The fine droplets created by the spray quickly dry due to the high surface area, resulting in a fine powder.

But why is this process so important in a laboratory setting? Spray dryers are crucial for several reasons:

Consistency and Reproducibility: Spray drying provides a high level of control over the particle size and moisture content of the resulting powder. This is essential for ensuring consistency and reproducibility in experimental results.

Preservation of Material Properties: Spray drying is a gentle process that helps preserve the bioactivity and other important properties of the materials being dried. This is particularly important in pharmaceutical and biochemical applications where the integrity of the material is critical.

Scalability: Spray drying can be easily scaled from laboratory to industrial production, making it a versatile tool for both research and manufacturing.

Applications of Spray Dryers in Laboratories

So, what are the specific uses of spray dryers in a laboratory? Here are some of the most common applications:

Pharmaceutical Research and Development

In pharmaceutical R&D, spray dryers are used to produce dry powders from liquid formulations. These powders can be used for various purposes, such as:

Drug Formulation: Spray drying can be used to create powders that are more stable and easier to handle than their liquid counterparts. This is especially important for drugs that are sensitive to heat or light.

Inhalable Drugs: Spray drying is often used to create fine powders for inhalation therapies. The small particle size produced by spray drying is ideal for this application, as it ensures the drug can be effectively delivered to the lungs.

Food and Beverage Industry

In the food and beverage industry, spray dryers are used to produce powdered ingredients, such as:

Dairy Products: Spray drying is commonly used to produce powdered milk and other dairy products. This extends the shelf life of the product and makes it easier to transport and store.

Flavors and Additives: Spray drying can be used to create powders from liquid flavorings and additives. This allows for precise control over the concentration and distribution of these ingredients in the final product.

Chemical and Materials Science

In chemical and materials science laboratories, spray dryers are used to create powders with specific properties, such as:

Catalysts: Spray drying can be used to produce catalyst powders with a high surface area, which enhances their effectiveness.

Nanomaterials: Spray drying can be used to produce nanomaterials with precise control over particle size and morphology. This is important for applications in electronics, optics, and other high-tech industries.

Biotechnology

In biotechnology, spray dryers are used to produce powders from biological materials, such as:

Proteins and Enzymes: Spray drying can be used to create stable, dry powders from protein and enzyme solutions. This helps preserve their bioactivity and extends their shelf life.

Vaccines: Spray drying can be used to produce powdered vaccines, which are easier to transport and store than their liquid counterparts.

The Benefits of Using a Spray Dryer

Now that we've covered some of the applications of spray dryers, let's take a closer look at the benefits they offer.

Saving Time and Resources

Spray drying is a highly efficient process that can significantly reduce the time and resources required to produce dry powders. Isn't it frustrating when traditional drying methods take forever and consume a lot of energy? With spray drying, you can achieve the same results in a fraction of the time, saving both time and money.

Improving Product Quality

Spray drying allows for precise control over the drying process, resulting in powders with uniform particle size and moisture content. This improves the quality of the final product and ensures consistency in experimental results.

Enhancing Stability and Shelf Life

Spray drying helps preserve the stability and bioactivity of sensitive materials, extending their shelf life and making them easier to store and transport. This is particularly important for pharmaceutical and biotech applications, where the integrity of the material is crucial.

Versatility and Scalability

Spray drying can be easily scaled from small laboratory batches to large industrial production, making it a versatile tool for a wide range of applications. This scalability also makes it easier to transition from research to commercial production.

Choosing the Right Spray Dryer for Your Laboratory

When selecting a spray dryer for your laboratory, there are several factors to consider:

Capacity

The capacity of the spray dryer is an important consideration, as it determines the volume of liquid that can be processed in a given time. Do you need a small-scale unit for research purposes, or a larger unit for pilot-scale production? Make sure to choose a spray dryer that meets your specific needs.

Temperature Control

Temperature control is crucial for ensuring the quality and stability of the final product. Look for a spray dryer with precise temperature control to ensure consistent results.

Particle Size Control

The ability to control particle size is another important feature to look for in a spray dryer. This is especially important for applications where particle size plays a critical role in the performance of the final product, such as inhalable drugs and nanomaterials.

Ease of Use and Maintenance

Finally, consider the ease of use and maintenance of the spray dryer. Look for a unit that is user-friendly and easy to clean, as this will save you time and effort in the long run.

Conclusion

In conclusion, spray dryers are invaluable tools in many laboratory settings, offering numerous benefits such as efficiency, consistency, and scalability. Are you ready to revolutionize your laboratory processes with a spray dryer? Whether you're working in pharmaceutical research, food science, chemical engineering, or biotechnology, a spray dryer can help you achieve your goals more efficiently and effectively.

Investing in a high-quality spray dryer is a smart move that can save you time and resources while improving the quality and stability of your products. So, if you haven't already, consider adding a spray dryer to your laboratory toolkit. You'll be amazed at the difference it can make!

What Are the Benefits of Spray Drying?

Spray drying is a fast, cost-effective method that turns liquids into powder. It preserves nutrients, extends shelf life, enhances consistency, and is widely ...

What is Spray Drying?

Spray drying is a process that transforms liquid or slurry into dry powder. It involves rapidly evaporating moisture with hot gas, producing fine, uniform par...

What is a Spray Dryer Used For?

A spray dryer transforms liquids into dry powders using hot gas. It's extensively used in food, pharmaceutical, chemical, and ceramic industries for producing...